The crystallization cooling stirring treatment equipment is a new type of lithium hydroxide (LiOH) crystallization equipment. We stir the β-spodumenea powder in a certain proportion after the process of acidified, roasting and cooling.Through the heat exchange between the stirring solution and coolant liquidin thesleeve, we can obtainlithium hydroxide grains, and provide quality guarantee for the next process-collectionof lithium hydroxide.

Technical Characteristics

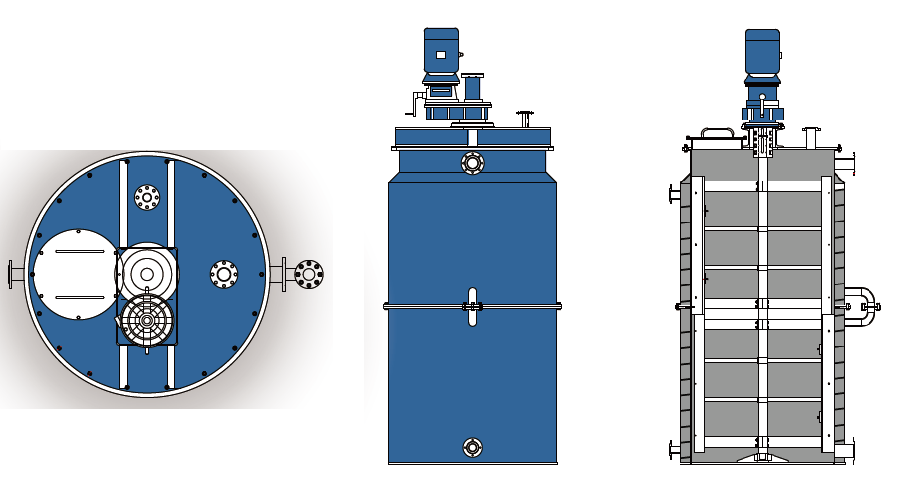

1)The spiral bladesaredesigned and installed in the sleeveof the cooling stirring tank. The coolant flows through the outer wall of the tankalong thespiralpath, so that the inner wall temperature of the crystallization coolingstirringequipment keeps the same, and the cooling of the solution is rapid and uniform.

2)For theicinginthe innerwall of thestirringtank ,the stirringblades aredesignedinto frame structure,on which wear resistant scraping strips are installed,andthespace between the strips and inner wall of stirring tankis about 1mm.The wear resistant scraping strips would remove the ice wall once it is formed,whichkeepsthe inside heat exchangeis uniform and reliable.

3)The wear resistant scraping strips are made ofimported wear-resistant steel plate, and the gap between thestrips and thetank wallisadjustable.

4)Lithium hydroxide(LiOH) grain sizeisuniformwithhigh leaching efficiency.

5)Continuous feeding and discharging.

6)According to the production quantity,we can choose thecrystallization coolingstirringequipmentwith differentdiameter ofφ1200,φ1400,φ1600,φ1800andφ2000,to meet the different productionrequirements. The non-standard crystallization coolingstirringequipment can also be designed and manufactured according to the process requirements.